When it comes to construction, mining, and other heavy-duty industries, core drill bits are indispensable tools. These specialized bits are designed to cut precise cylindrical holes in a variety of materials, including concrete, stone, and metal. However, one question that often arises among professionals and DIY enthusiasts alike is:Are core drill bits reverse thread?

The short answer is no—core drill bits are not typically reverse thread. But to fully understand why, it’s important to delve into the mechanics of core drill bits, their threading, and how they function in conjunction with drilling equipment.

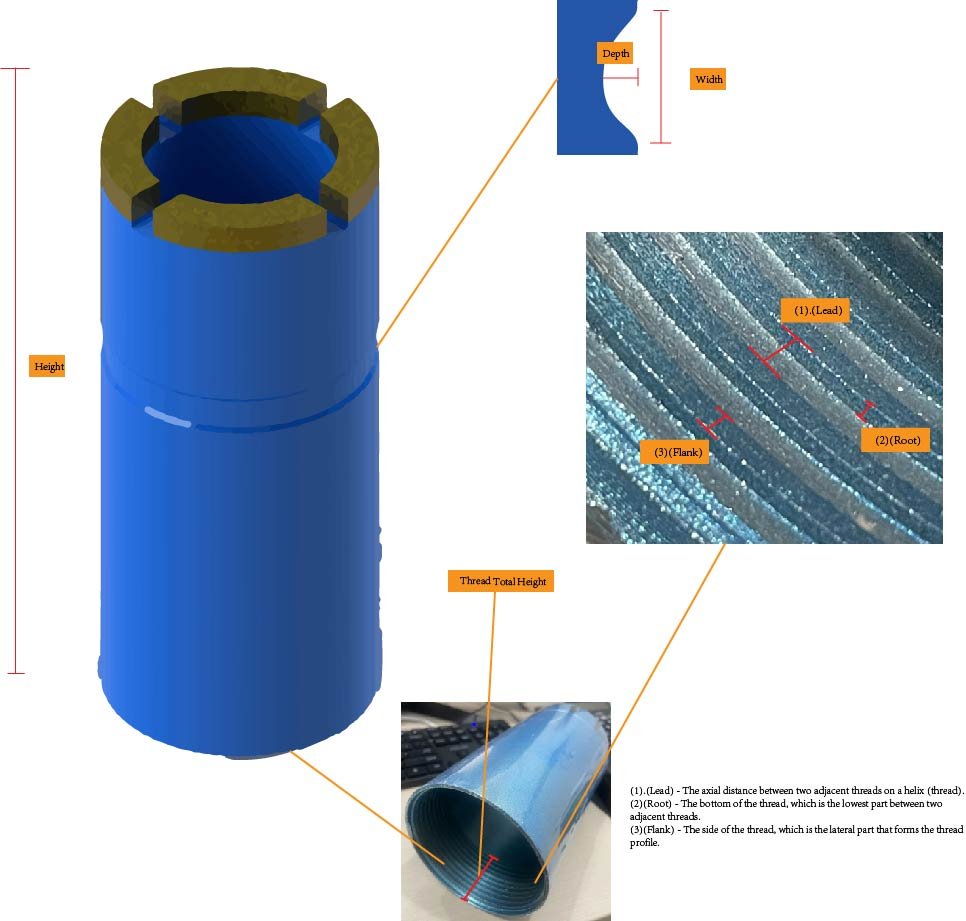

What Is Threading on a Core Drill Bit?

Threading refers to the spiral grooves on the shank of a drill bit or the corresponding part of the drill rig. These threads allow the bit to securely attach to the drill’s spindle or chuck. The threading ensures that the bit remains stable during operation, even under the intense forces generated by high-speed drilling.

Most core drill bits use standard threading, which is designed to tighten in the same direction as the drill’s rotation—typically clockwise. This is known as a “right-hand thread.” The reason for this design is simple: as the drill rotates, the threading naturally tightens, preventing the bit from loosening during use.

Why Aren’t Core Drill Bits Reverse Thread?

Reverse threading, or “left-hand threading,” is uncommon in core drill bits for several reasons:

- Compatibility with Drill Motors: Most drill motors and rigs are designed to rotate clockwise. Using reverse-threaded bits would require specialized equipment, which is not standard in the industry.

- Safety and Stability: A reverse-threaded bit could loosen during operation if used with a standard clockwise-rotating drill. This could lead to dangerous situations, including damage to the equipment or injury to the operator.

- Ease of Use: Standard threading simplifies the process of attaching and detaching bits. Operators can rely on the natural tightening action of the drill’s rotation to secure the bit, reducing the risk of errors.

Are There Any Exceptions?

While core drill bits are not typically reverse thread, there are some specialized tools and applications where reverse threading is used. For example, left-hand drill bits are sometimes employed to remove broken screws or bolts, as their reverse threading allows them to grip and extract the damaged fastener. However, these are not core drill bits and serve a very different purpose.

In rare cases, certain drilling systems may use reverse-threaded components, but these are exceptions rather than the rule. If you’re working with a unique or highly specialized drill rig, it’s always a good idea to consult the manufacturer’s specifications to ensure compatibility.

Key Takeaways for Professionals

For most standard applications, you can rest assured that core drill bits are not reverse thread. When purchasing or using core drill bits, here are a few tips to keep in mind:

- Check Compatibility: Always ensure that the bit’s threading matches your drill rig or motor. Most systems use standard right-hand threading.

- Inspect for Wear: Over time, threads can wear down, potentially compromising the connection between the bit and the drill. Regular inspections can help prevent accidents.

- Follow Manufacturer Guidelines: Each drill and bit may have specific requirements. Adhering to these guidelines ensures optimal performance and safety.

Conclusion

Core drill bits are a cornerstone of many industries, prized for their precision and durability. While the question of reverse threading may arise, the vast majority of core drill bits are designed with standard right-hand threading to ensure compatibility, safety, and ease of use. By understanding the basics of core drill bit design, professionals can make informed decisions and achieve the best results in their projects.

So, the next time you’re gearing up for a drilling job, you can confidently say: core drill bits are not reverse thread—and now you know why.